Compost Master: Why Are Windrow Compost Turning Machine So Remarkable?

In contemporary agriculture, transforming organic waste into premium fertilizer represents a critical sustainability practice. The windrow compost turning machine, an innovative fertilizer production machine, has revolutionized traditional composting methods with its exceptional efficiency, effectively converting agricultural waste into valuable “black gold.”

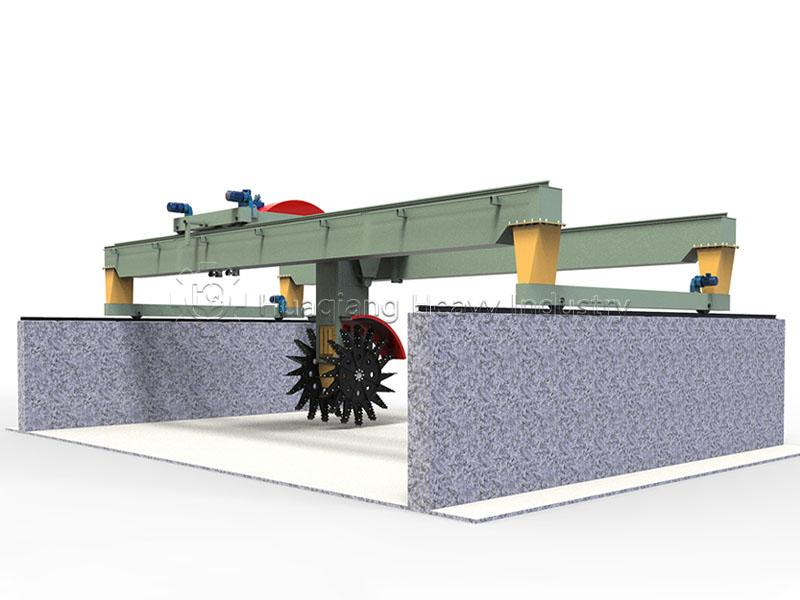

This advanced fertilizer making machine operates as a specialized windrow compost turning machine that systematically aerates and mixes organic materials, accelerating the decomposition process while eliminating pathogens and weed seeds.

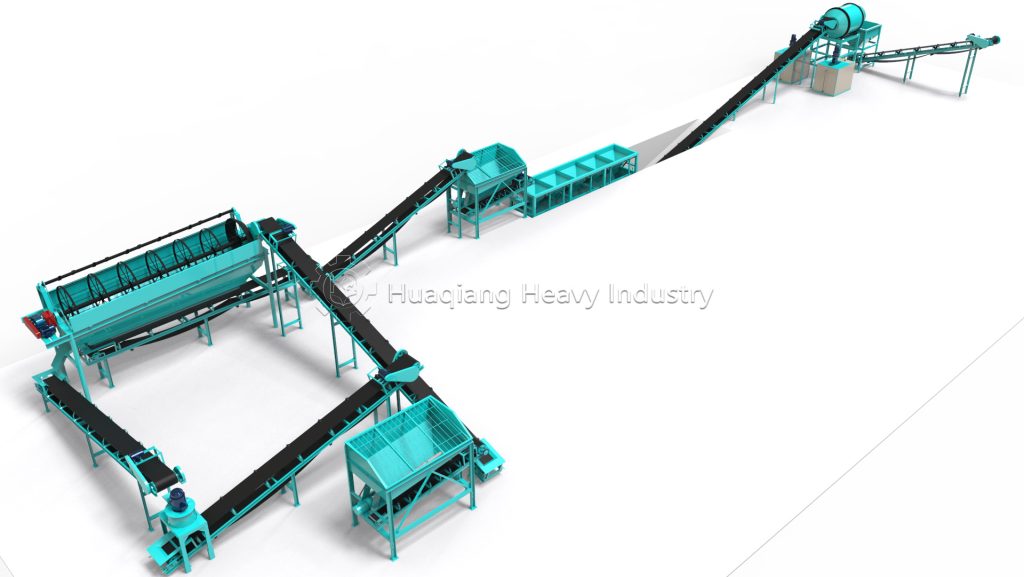

The complete fertilizer production workflow integrates multiple technologies:

Organic Waste Collection

→

Windrow Composting

→

Granulation Process

→

Quality Fertilizer

Following the composting phase, the resulting material can be further processed through fertilizer granules compaction techniques to create uniform, easy-to-apply fertilizer products. This integrated approach demonstrates how modern fertilizer production machines work synergistically to transform waste into valuable agricultural resources, contributing to circular economy principles in farming.

By optimizing aeration, moisture control, and temperature regulation, these advanced systems significantly reduce composting time while enhancing nutrient retention in the final product—delivering both economic and environmental benefits to modern agricultural operations.

The most remarkable feature of this extraordinary fertilizer machine is its outstanding ground adaptability. The tracked design enables stable operation across various complex terrains—whether rugged, soft, muddy, or slippery surfaces, it handles them all with ease. Its well-designed turning mechanism penetrates deep into the pile, achieving efficient and uniform turning and mixing, ensuring every part of the raw materials receives adequate oxygen.

The automation level of this fertilizer production machine is truly impressive. The intelligent control system automates both turning and travel operations, significantly reducing manual intervention while enhancing production efficiency.

Environmental protection and energy efficiency are additional highlights. It effectively promotes the resource utilization of organic waste, reduces environmental pollution, and operates with low energy consumption, aligning perfectly with sustainable development principles. The tracks and turning mechanism, crafted from durable materials, ensure long-lasting performance even under prolonged, high-intensity operations.

Windrow compost turning machine represent not just a revolution in composting technology but a powerful force driving green agricultural development, providing perfect solutions for the resource utilization of organic waste.

.jpg)