Comparison of organic fertilizers and biofertilizers: Advantages, applications and optimal application strategies

In modern agricultural production, organic fertilizers and bio-fertilizers are valued for their environmentally friendly properties and for promoting soil health. This article will compare the two fertilizers and discuss their advantages, applications and best application strategies.

The advantage and application of organic fertilizer

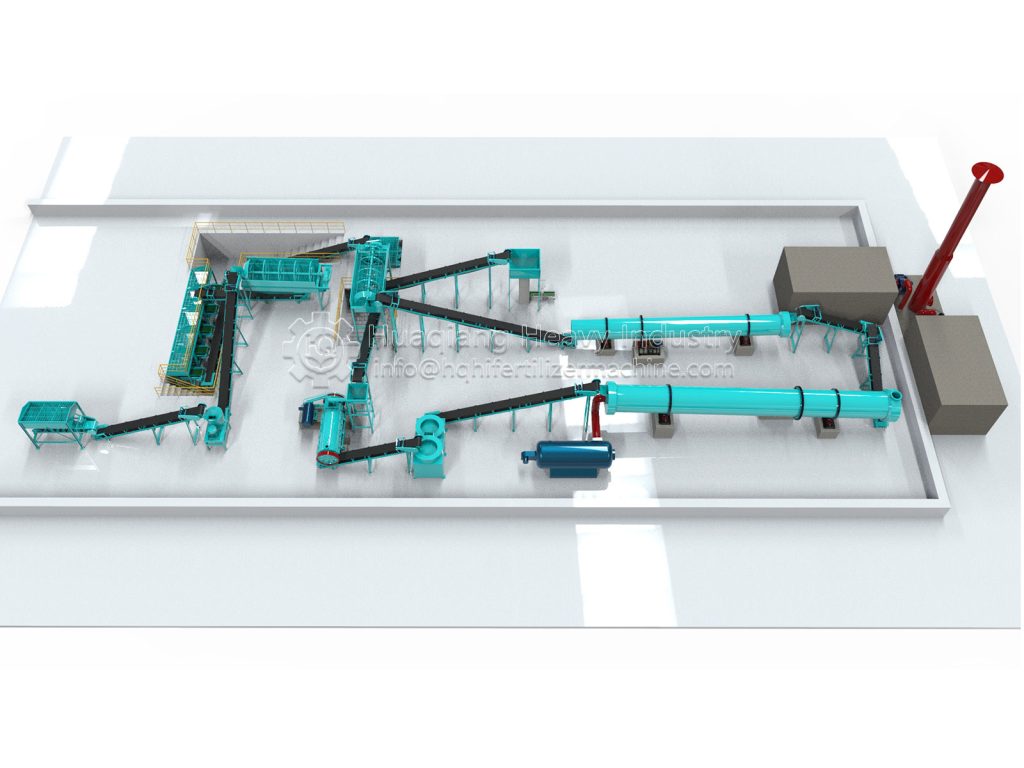

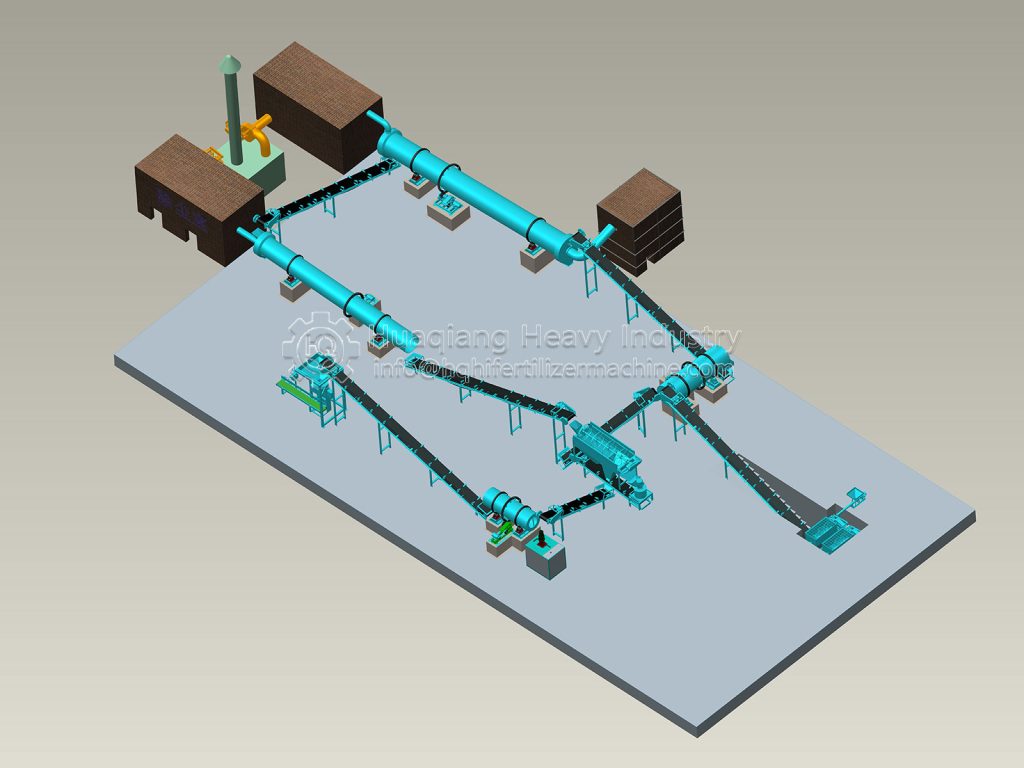

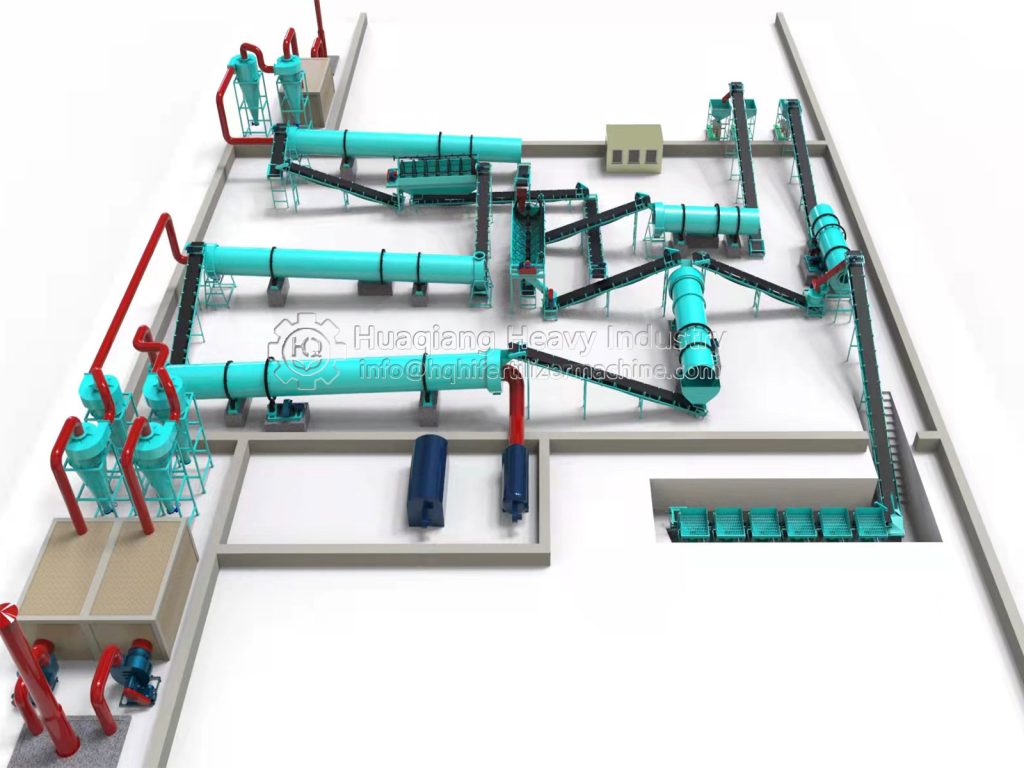

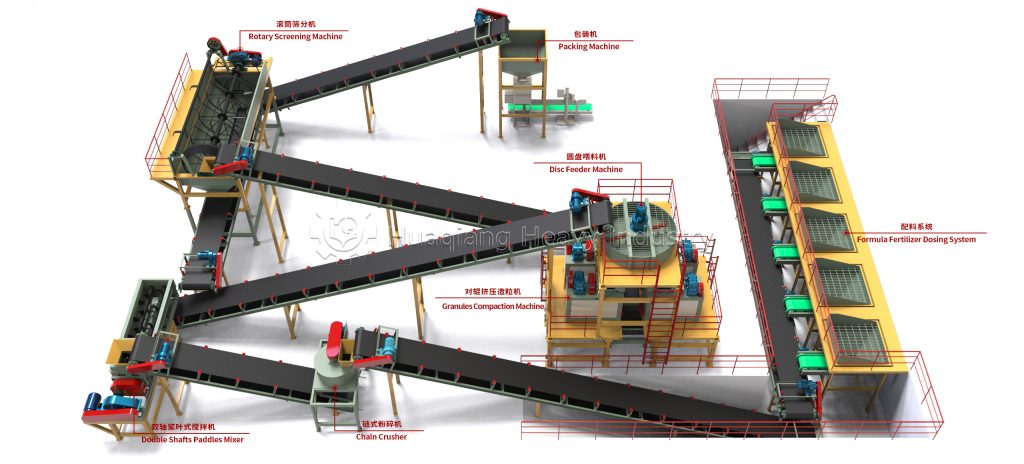

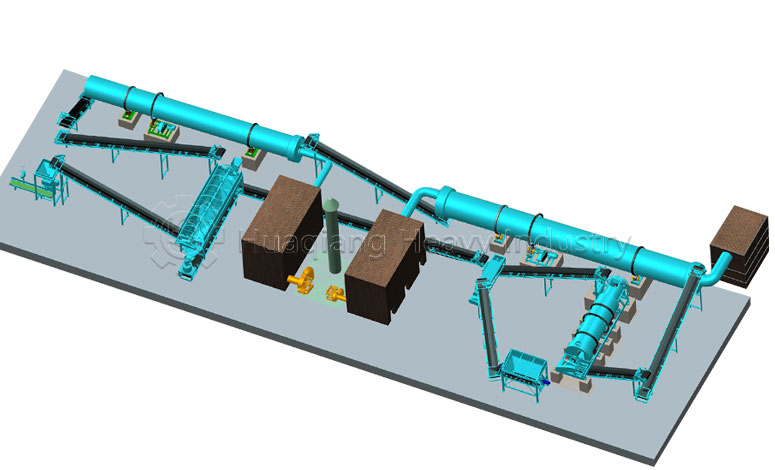

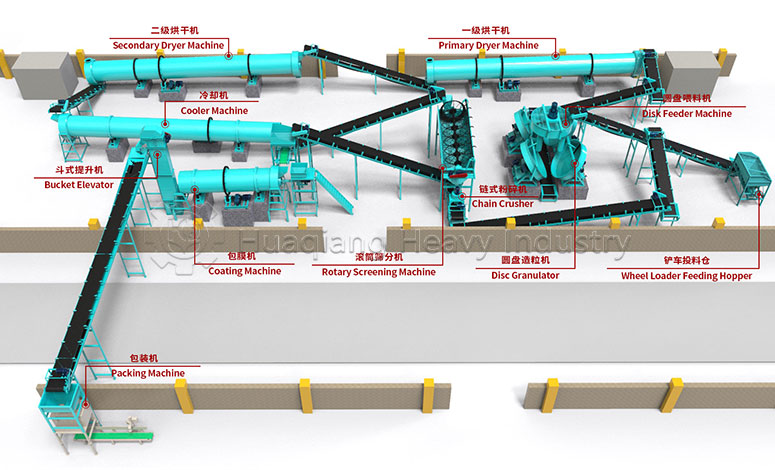

Organic fertilizers, such as compost and green manure, are fertilizers obtained through the decomposition and conversion of organic matter. They provide a variety of nutrients needed by plants and improve soil structure. Organic Fertilizer Production Line can produce organic fertilizers suitable for different crops according to different organic raw materials, such as animal and plant residues. These fertilizers have a remarkable effect in increasing soil fertility and crop yield.

Advantages and applications of biofertilizers

Biofertilizers, such as microbial inoculants, contain beneficial microorganisms that promote plant growth. They work by enhancing the root development of plants and improving the availability of nutrients in the soil. The Production of biofertilizers usually involves the NPK Fertilizer Production Line to ensure that the necessary nutrients are contained in the fertilizer.

Optimal application strategy

In order to maximize the effectiveness of organic fertilizers and biofertilizers, appropriate application strategies are required. First, the right type of fertilizer should be selected according to the needs of the crop and soil conditions. Secondly, the timing of application is also important, and it is usually carried out during the critical period of crop growth. In addition, the application amount and method of fertilizer also need to be adjusted according to the specific situation.

Application of fertilizer granulator equipment

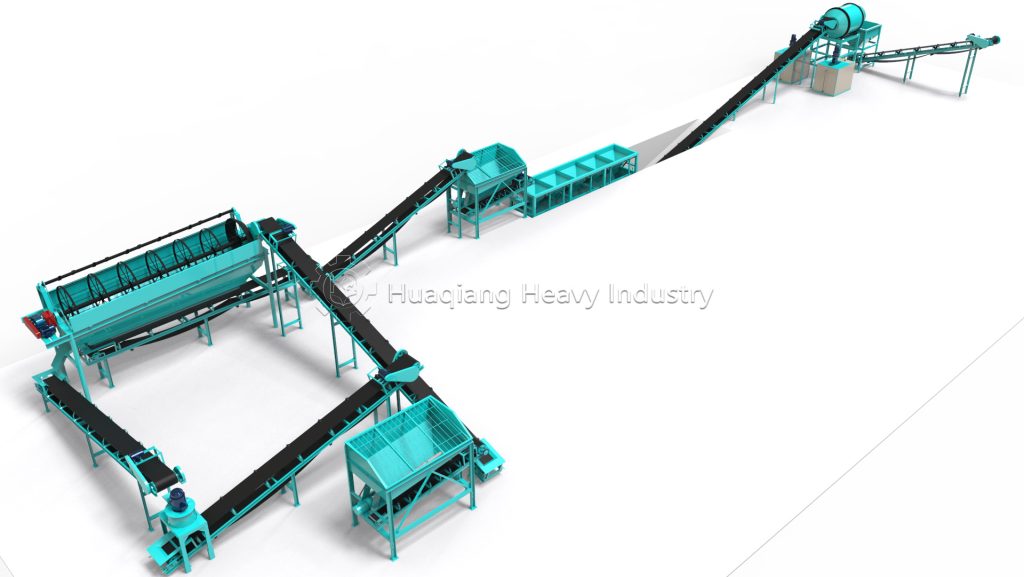

In the production process of fertilizer, fertilizer granulator equipment plays an important role. Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine can process organic fertilizer and biofertiliser raw materials into pellets for easy application and storage. Rotary Drum Granulator and Disc Granulator use different granulation techniques to produce fertilizer pellets suitable for different crops and soil condition.

Conclusion

Organic fertilizers and bio-fertilizers each have their own unique advantages, and both play an important role in increasing crop yields and improving soil health. The effectiveness of these fertilizers can be maximized through rational application strategies and advanced fertilizer granulator equipment. In the future, with the continuous progress of agricultural technology, organic fertilizers and bio-fertilizers will play a more important role in sustainable agriculture.