Modular design: A new approach to NPK fertilizer production

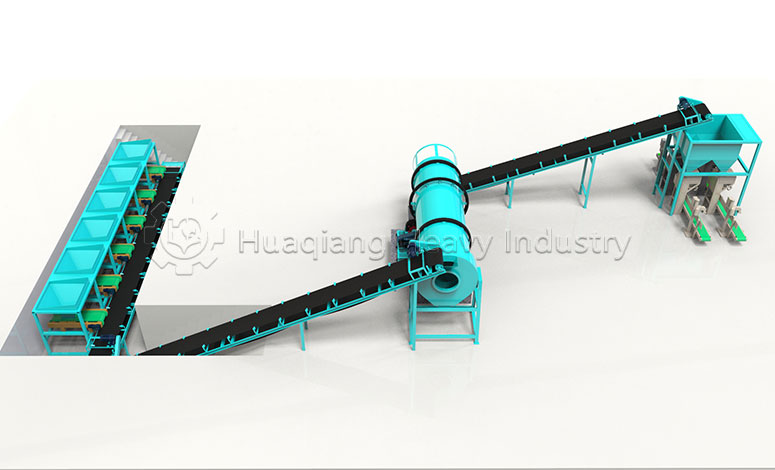

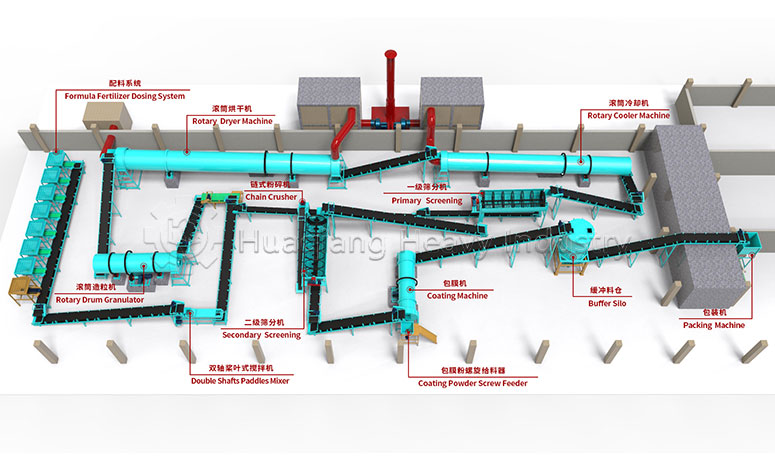

Traditional NPK fertilizer production lines typically have a fixed layout, while modular design is becoming a new trend. This design divides the entire NPK fertilizer production line into independent functional units, improving the flexibility of equipment configuration and production management.

The raw material processing module is responsible for receiving and initial crushing. Raw materials of different forms are fed into a temporary storage bin via lifting equipment, providing suitable materials for the subsequent NPK blending machine. This design also reserves interfaces for the introduction of bio-organic fertilizer equipment, enhancing the diversity of formulations.

The core batching system uses a multi-bin combination with weighing units. Raw materials are conveyed to the central mixing zone according to preset proportions, where they are mixed by a high-efficiency NPK blending machine (also known as a fertilizer mixer machine). The entire process is automatically completed by the control system, ensuring the accuracy of the proportions.

The mixing and packaging modules are tightly integrated. Modern fertilizer mixer machines achieve uniform mixing of materials in a short time, and the finished product is directly transported to the packaging scale through a closed pipeline. This layout effectively prevents material segregation and is particularly suitable for handling NPK formulations with large differences in specific gravity.

The modular design enables the NPK fertilizer production line to be quickly adjusted according to market demand. While mainly producing NPK compound fertilizer, it also creates conditions for the introduction of bio-organic fertilizer equipment, enhancing the adaptability of the production line.