Analysis of key factors affecting the quality of organic fertilizer granules

The quality of organic fertilizer granules directly impacts fertilization effectiveness, ease of storage and transportation, and product market competitiveness. Its formation process is constrained by multiple factors in the production chain.

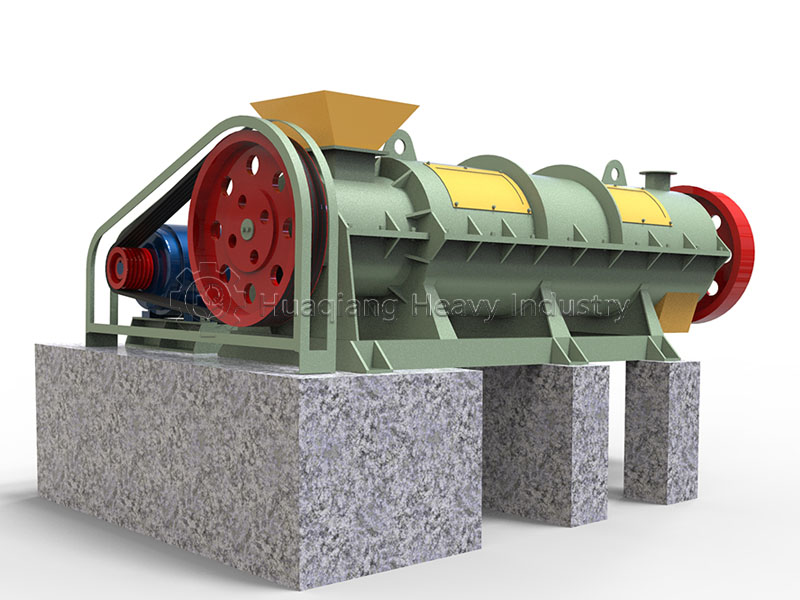

Raw material characteristics are fundamental. The organic matter content, particle size distribution, and impurity content of the raw materials are crucial. The organic matter content needs to be maintained within a suitable range; too low a content will lead to poor granule formation and insufficient strength. Uneven raw material particle size can easily result in inconsistent granule size. It is recommended to crush the raw materials to a reasonable fineness beforehand, and then thoroughly mix and screen them to remove impurities using a fertilizer mixer machine. Furthermore, an imbalance in the carbon-nitrogen ratio of the raw materials will affect the subsequent fermentation process, indirectly leading to easily loosened granules.

Moisture content is a core condition for granulation. During granulation, the moisture content of the raw materials needs to be controlled between 25% and 35%. Excessive moisture can easily cause granules to stick together and clump, and may also lead to secondary fermentation during storage; insufficient moisture results in poor raw material fluidity, making it difficult to agglomerate and form granules, which are then prone to breakage. During production, the moisture content needs to be dynamically adjusted based on the type of raw material and the operating status of the bio-organic fertilizer equipment to ensure the stability of the granulation process.

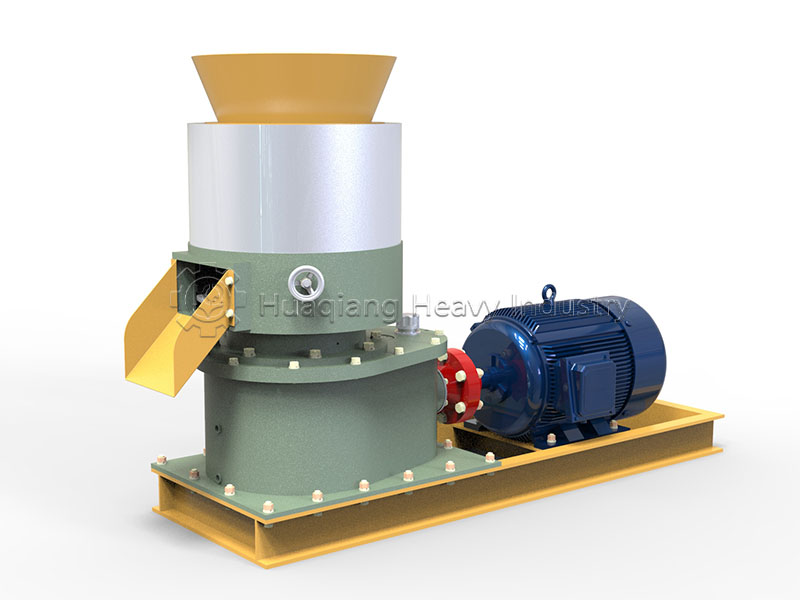

Fertilizer granulator parameters and fermentation process should also not be overlooked. The speed, pressure, and inclination angle of different types of fertilizer granulators (such as disc granulators and flat die pelleting machines) directly affect the uniformity and strength of the granules; insufficient fermentation and maturation in the early stages will lead to residual undecomposed substances in the raw materials, resulting in a loose internal structure of the granules and making them prone to cracking and pulverization.

In summary, controlling key aspects such as raw material screening, fertilizer mixer blending, moisture adjustment, fertilizer granulator debugging, and fermentation control is essential to consistently produce high-quality organic fertilizer granules.