How can you use new type organic fertilizer granulators more efficiently and save energy and materials?

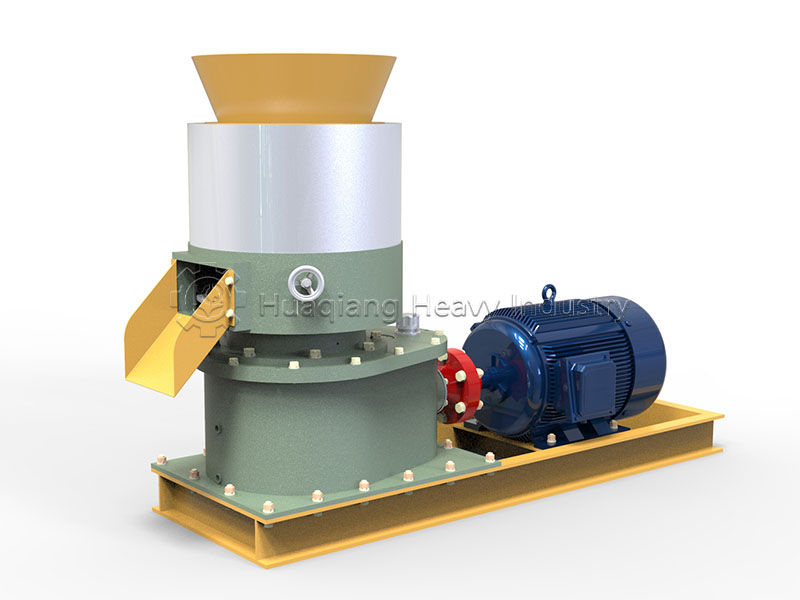

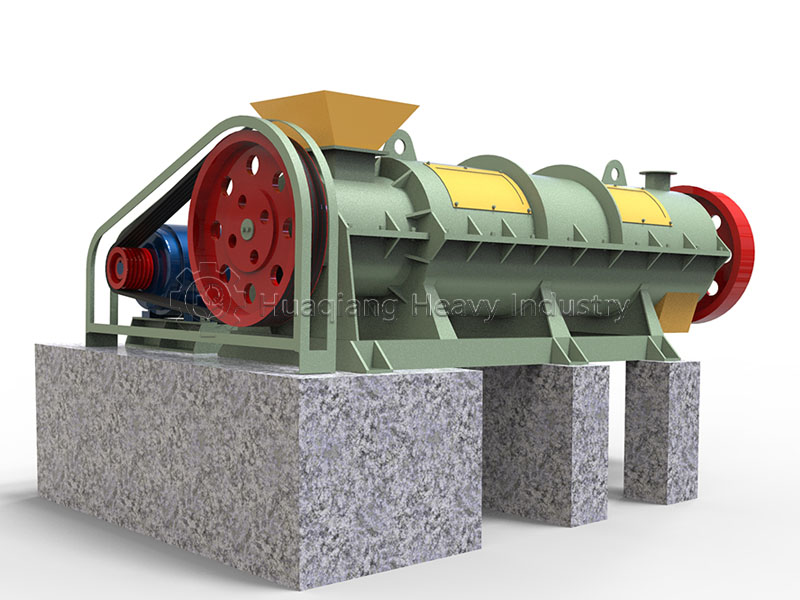

Many organic fertilizer plants are concerned about costs. However, when using new type organic fertilizer granulators, paying attention to two small details can significantly save energy and materials.

To save energy, most new type organic fertilizer granulators are equipped with variable-frequency motors. Avoid running them at maximum speed all the time. For example, when initially feeding, use a low speed of 15 rpm. Once the raw materials have stabilized in the granulation chamber, gradually increase the speed to 20-25 rpm. This prevents the motor from exerting sudden force, saving 10%-15% of energy per hour. Additionally, avoid idling the machine. Do not start the machine until the raw materials are ready. The energy wasted in idling for one hour is enough to generate granules for 20 minutes.

To save materials, the key is to reduce waste. New type organic fertilizer granulators have a return device. Instead of discarding the crushed granules, they are directly returned to the granulation chamber through the return port, where they are mixed with new raw materials and granulated again. This can reduce the waste rate from 10% to less than 3%. Also, do not mix impurities such as stones and iron wire into the raw materials. Impurities will wear out machine parts and crush good particles. Use a sieve before feeding each time to avoid a lot of material waste.