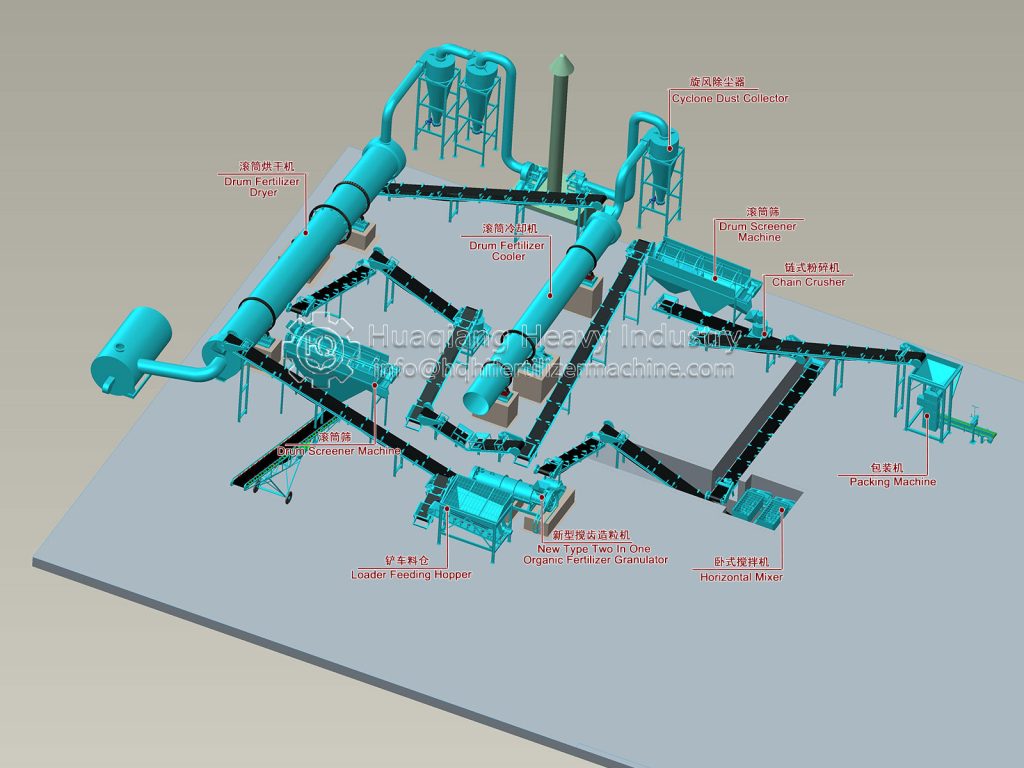

Key points for retrofitting organic fertilizer production lines under environmental compliance requirements

With increasingly stringent environmental protection policies, environmental retrofitting of organic fertilizer production lines has become an industry imperative, focusing on the treatment of “three wastes” and compliance upgrades.

For waste gas treatment, organic fertilizer production lines must be equipped with sealed fermentation chambers and ammonia collection systems. Biofilter technology is used to control ammonia concentrations generated during the fermentation process to within standards. Some areas also require VOC monitoring equipment to ensure real-time upload of emission data.

For wastewater treatment, production lines must establish a recycling system to sediment and filter wash water and condensate before reusing them for raw material moisture conditioning, achieving zero wastewater discharge.

For solid waste treatment, optimized screening processes are employed to re-crush fermentation residues before mixing them back into fermentation, achieving full solid waste utilization.

Furthermore, the environmental impact assessment process imposes stricter requirements on production line site selection and capacity planning, such as requiring them to be at least 500 meters away from residential areas and designing production capacity to match the regional environmental carrying capacity. Although these transformations increase initial investment (usually the transformation cost of a single production line accounts for about 15%-20% of the total investment), the energy consumption of the organic fertilizer production line can be reduced by 12%-18% after the transformation.