Double roller press granulator: Granulation equipment for NPK fertilizer production lines

NPK compound fertilizers, due to their balanced nutrients and suitability for various crops, have become the mainstream fertilizer in agricultural production. The core efficiency of an NPK fertilizer production line largely depends on the selection of the fertilizer granulator. Among them, the double roller press granulator, with its unique advantages, has become the preferred granulation equipment for many NPK production lines, helping to achieve efficient and low-cost granulation.

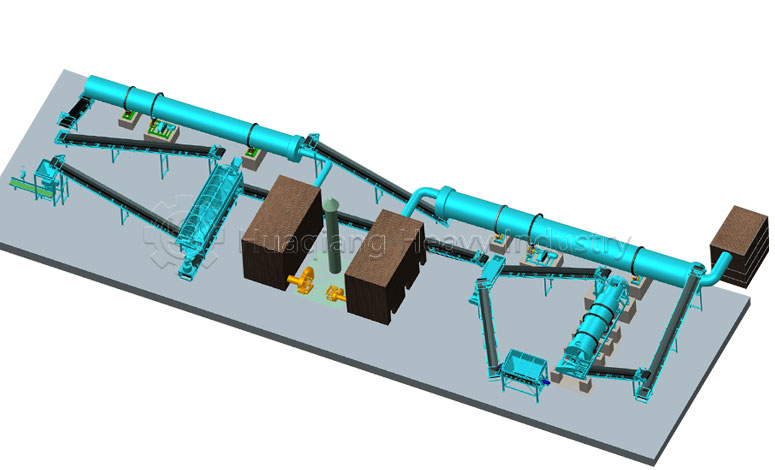

In an NPK fertilizer production line, the double roller press granulator is at the core. Pre-treated nitrogen, phosphorus, and potassium raw materials and fillers are uniformly mixed by a fertilizer mixer machine and then fed into this equipment. The pressure generated by the relative extrusion of the double rollers directly forms the material into granules, without the need for additional water or binders. This dry granulation method eliminates subsequent drying and cooling steps, significantly simplifying the NPK production line process and reducing energy consumption and production costs.

As one of the mainstream fertilizer granulators, the double roller press granulator has significant advantages in NPK production. It has strong adaptability to raw material moisture content, capable of processing materials with a moisture content of 8%-15%, avoiding the clumping problems that often occur in wet granulation; it has a high granulation rate, and the granules have high strength and are not easily broken, meeting the needs of NPK compound fertilizer storage, transportation, and mechanized fertilization. In addition, the equipment has a simple structure and is easy to operate, and can be easily connected with supporting equipment such as fertilizer screener machines and packaging machines, adapting to NPK fertilizer production lines of different scales.

Whether for small and medium-sized NPK production projects or large-scale production lines, the double roller press granulator can adapt to the needs with its flexible capacity adjustment capabilities. It not only improves the production efficiency of NPK fertilizers but also ensures the quality stability of the finished fertilizer, becoming an important equipment support for promoting the high-quality development of the NPK compound fertilizer industry.