Key considerations for drum fertilizer dryer selection

For fertilizer companies, choosing the right drum fertilizer dryer not only ensures effective drying but also reduces subsequent energy consumption and maintenance costs.

1. Suitable Heating Method for Fertilizer Type

For organic fertilizer production (including fiber-based fermented materials), the preferred option is “hot air heating.” Direct contact between the hot air and the material results in faster drying and prevents fiber sticking to the wall. For compound fertilizer production (wet granules after granulation), the “steam heating” option offers a milder temperature and reduces granule breakage. For low-temperature drying of biofertilizers (to prevent inactivation of microbial inoculants), the “low-temperature hot air” option is recommended to preserve microbial activity.

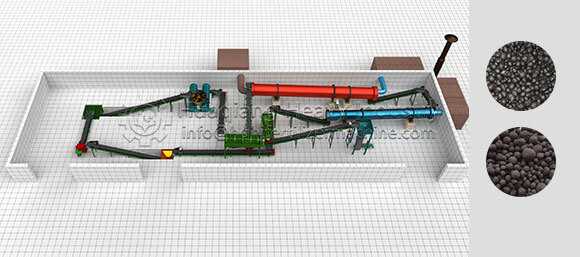

2. Matching Drum Specifications to Production Capacity

The drum diameter and length directly determine the processing capacity. When selecting a drum fertilizer dryer, calculate the hourly processing capacity based on the daily production capacity, allowing for a 10%-15% margin to ensure sufficient material residence time.

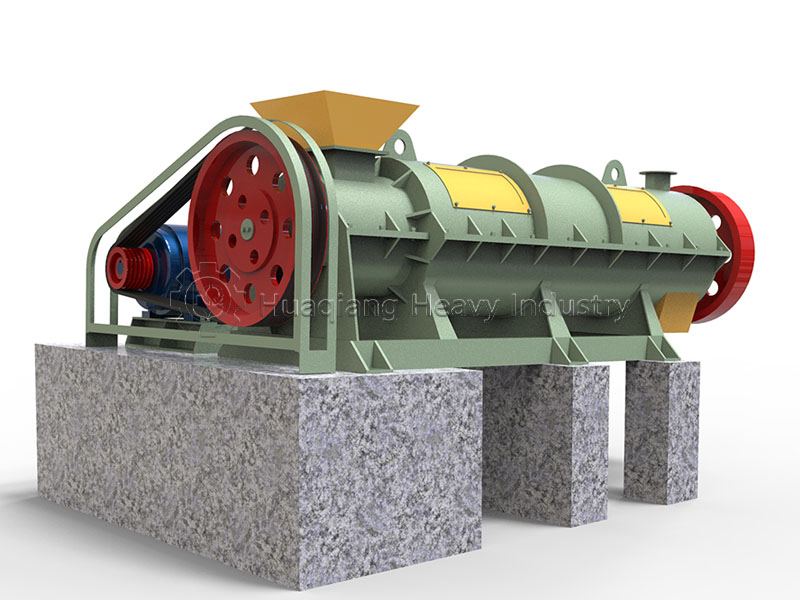

3. Targeted Selection of Anti-Stick Designs

High-humidity organic fertilizers tend to stick to the inner wall of the drying drum. When selecting a drum fertilizer dryer, confirm whether it features an anti-sticking skimmer or polished inner wall treatment to reduce material residue and avoid frequent downtime for cleaning. When processing highly sticky wet compound fertilizer pellets, a combination of a guide plate and skimmer can be used to guide material flow smoothly.

4. Energy Consumption and Environmental Parameters

Prioritize equipment with high thermal efficiency to reduce fuel waste. Also, consider the suitability of exhaust gas treatment. The hot and humid exhaust gas generated during the drying process requires dust removal and desulfurization equipment to ensure compliance with environmental emission standards in the fertilizer industry.