Efficient organic fertilizer production: From compost turners to complete production line selection

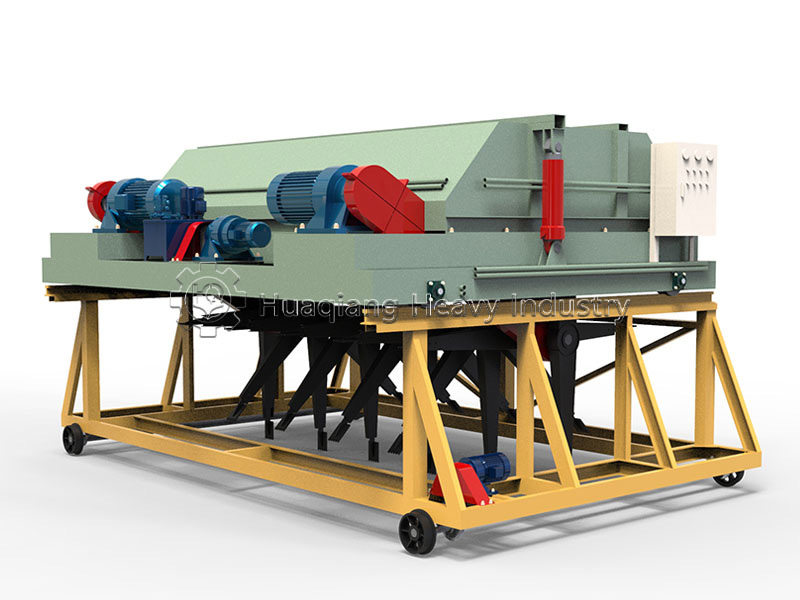

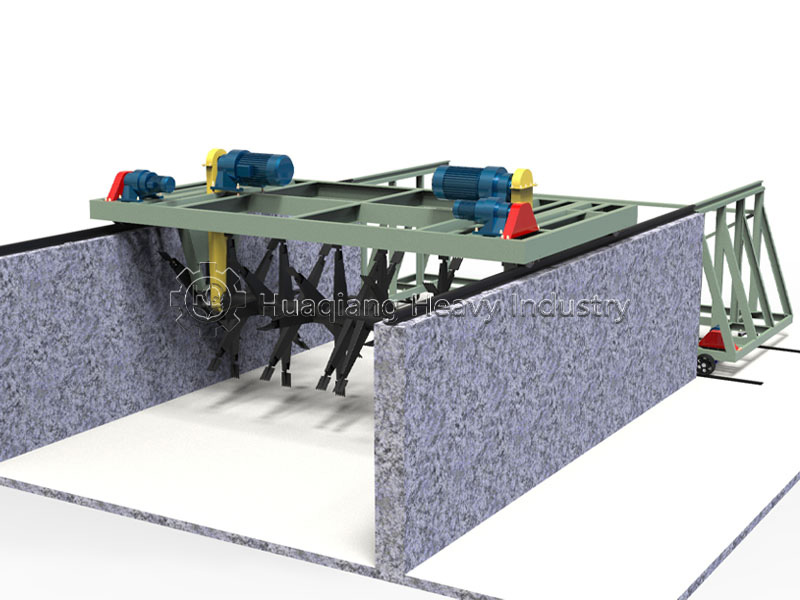

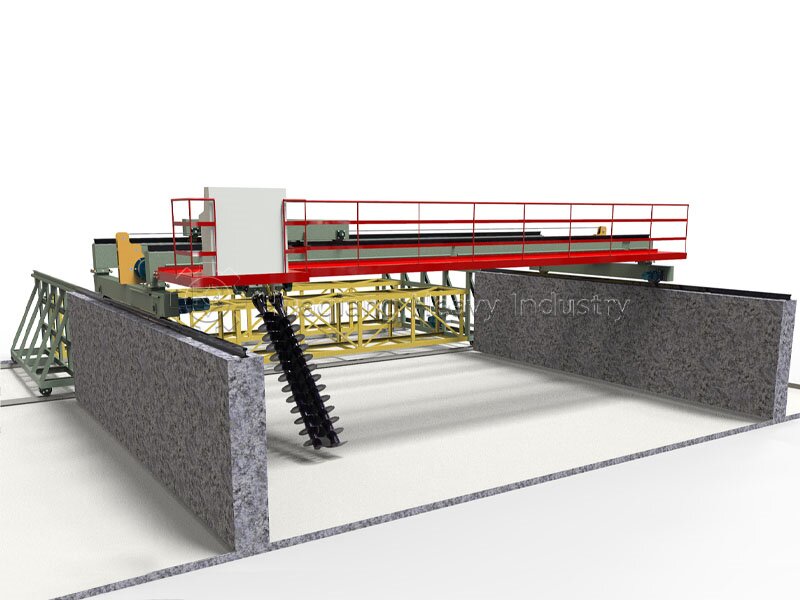

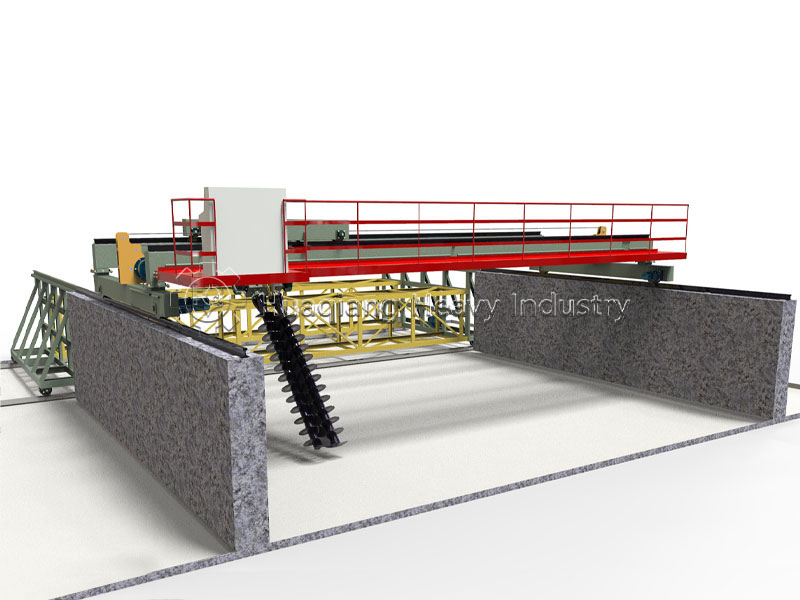

In the context of green agricultural development and waste resource utilization, efficient organic fertilizer production equipment has become crucial. Compost turning machines, as the core equipment in the organic fertilizer fermentation process, directly impact fermentation efficiency and fertilizer quality. Among these, the double screws compost turning machine stands out due to its unique advantages. It utilizes a double-helix stirring structure to penetrate the compost pile for even mixing, and is equipped with an oxygen supply system to meet the needs of aerobic fermentation. This accelerates the decomposition of organic materials such as livestock manure and crop straw, significantly improving fermentation efficiency. It is widely applicable to agricultural waste treatment and organic fertilizer production.

In addition to the double-helix model, various other compost turners are available for different needs. For example, hydraulic compost turning machines are suitable for large production sites, offering powerful performance and stable operation; windrow compost turning machines are flexible and adaptable to open-air windrow fermentation; and simple compost turning machines are cost-effective, meeting the basic fermentation needs of small farms or startups. These devices, through precise composting and turning operations, lay the foundation for high-quality raw materials in organic fertilizer production.

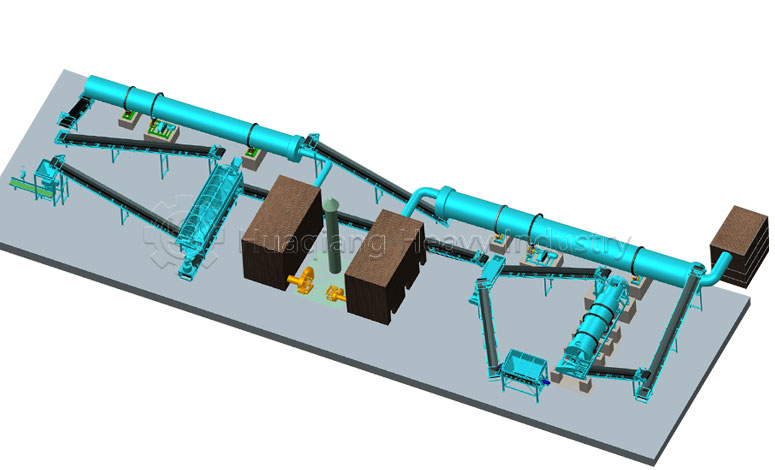

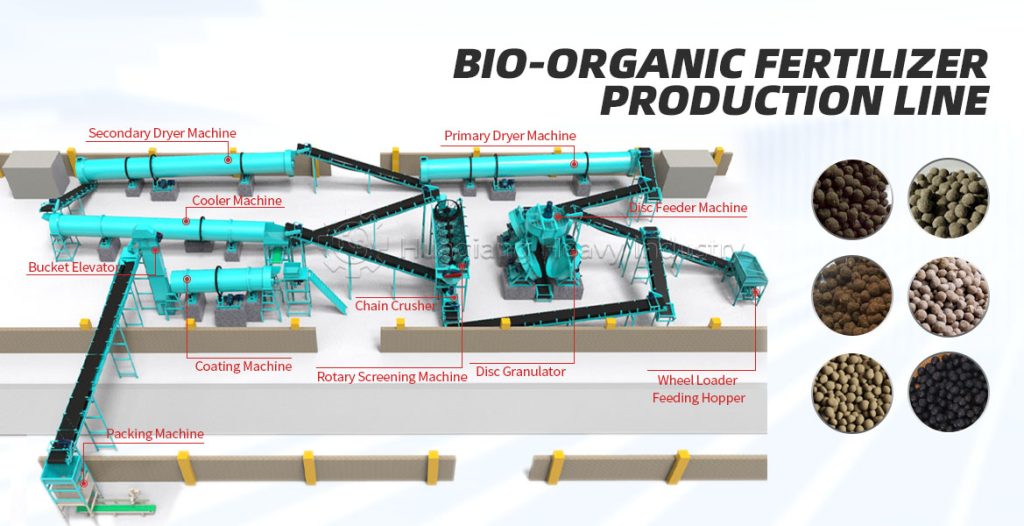

A complete organic fertilizer production line also requires other key equipment. To expand the product line, NPK fertilizer production lines can achieve diversified fertilizer production, while bio-organic fertilizer production lines focus on the development of high-value bio-fertilizers. Furthermore, fertilizer granulators can process the fermented materials into granular form, improving product storage and transportation convenience and market competitiveness.

Choosing the right combination of equipment not only promotes the resource utilization of organic waste and reduces environmental pollution, but also helps agricultural production achieve a green cycle, injecting momentum into sustainable agricultural development.