In-depth Analysis of Aerobic Fermentation Technology

In the field of organic fertilizer production, aerobic fermentation technology has become the most mainstream treatment method worldwide due to its maturity, stability, efficiency, and environmental friendliness. Through scientifically controlling microbial activity, this technology transforms organic waste such as crop straw and livestock manure into high-quality organic fertilizer, achieving dual goals of resource recycling and environmental protection.

Principle of Aerobic Microbial Conversion

The core of aerobic fermentation lies in utilizing the metabolic activities of aerobic microorganisms such as Bacillus and Actinomycetes. Under oxygen-sufficient conditions, these microorganisms can efficiently decompose complex macromolecular substances like proteins, cellulose, and fats in organic raw materials. During decomposition, microorganisms release significant heat through respiration, raising pile temperature to 55-70°C. This creates suitable growth conditions for microorganisms while achieving harmless treatment of raw materials.

Temperature control is crucial in this process. Ideal fermentation temperatures not only promote rapid organic matter decomposition but also effectively eliminate pathogens, insect eggs, and weed seeds with eradication rates exceeding 95%. Simultaneously, high-temperature environments facilitate the action of specialized microorganisms like cellulose-decomposing bacteria, accelerating the transformation of difficult-to-degrade materials such as straw.

Systematic Fermentation Process

Successful fermentation requires strict process control. During pretreatment, raw materials undergo crushing and mixing, while adjusting the carbon-to-nitrogen ratio to the ideal range of 25-30:1 and moisture content to 55-60%. Scientific control of these parameters creates optimal conditions for microbial activity.

Depending on production scale and site conditions, fermentation can adopt different forms such as windrow, trough, or tower systems. Windrow fermentation suits small to medium-scale production with lower costs and operational flexibility; trough fermentation better suits large-scale factories providing more stable fermentation environments; tower fermentation, with its high automation and small footprint advantages, becomes the preferred choice for large production lines.

Key Control Factors and Operational Essentials

Turning operations are critical to ensuring fermentation success. By regularly turning compost piles, fresh oxygen is replenished, temperature and humidity are regulated, and efficient microbial activity is maintained. Generally, turning operations are required every 1-2 days during fermentation.

The length of fermentation cycles depends on multiple factors, typically ranging from 7-21 days. Intuitive standards for determining fermentation completion include: color changing from yellowish-brown to dark brown, disappearance of pungent odors, pile temperature dropping to ambient levels, and materials becoming loose. Professional production also requires testing organic matter content, total nutrients, and other indicators to ensure compliance with national standard requirements.

Practical Applications and Global Promotion

In places like Shouguang, China, aerobic fermentation technology has been successfully applied to large-scale organic fertilizer production. Local vegetable bases adopt a “straw + chicken manure” raw material combination, achieving annual processing capacity of 200,000 tons of organic waste through windrow fermentation. This successful case fully demonstrates the practicality and economic viability of aerobic fermentation technology.

The global popularity of this technology stems from its multiple advantages: significant environmental benefits with resource utilization rates reaching over 80%; relatively low equipment investment with high localization rates; strong adaptability capable of processing various types of organic waste. With the development of intelligent technology, modern fermentation systems have achieved real-time monitoring and automatic control of parameters like temperature and humidity, further improving production efficiency and product quality.

Future Development Trends

As global emphasis on sustainable agriculture and environmental protection continues to increase, aerobic fermentation technology will continue to develop and improve. The development of intelligent control systems, specialized microbial agents, and integration with other treatment technologies will promote this traditional technology toward more efficient and environmentally friendly directions.

Aerobic fermentation technology not only addresses the challenge of organic waste treatment but also provides high-quality organic fertilizer for agricultural production, promoting soil health and agricultural sustainable development. The continuous innovation and application promotion of this technology will play an increasingly important role in the construction of global circular agricultural systems.

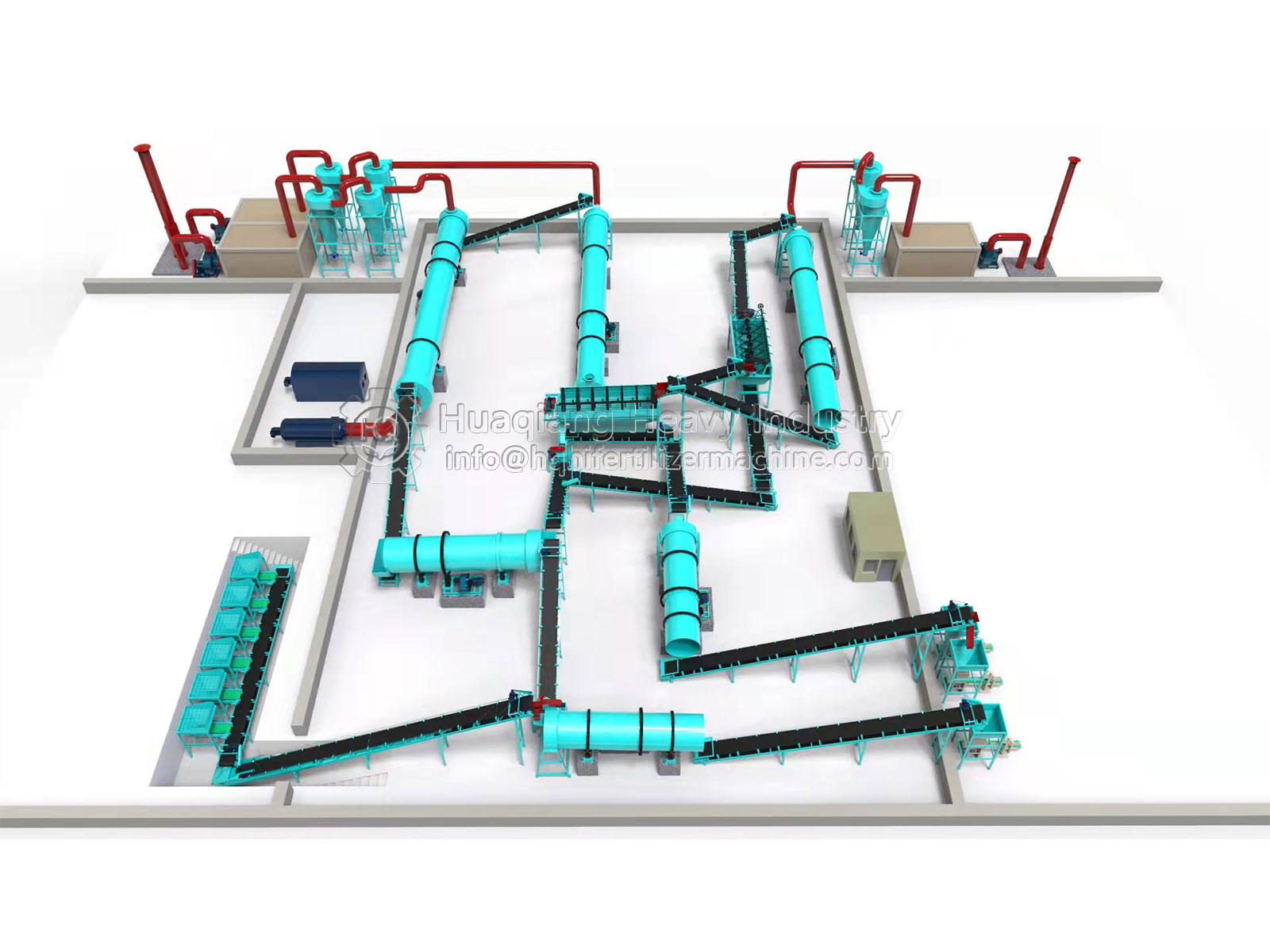

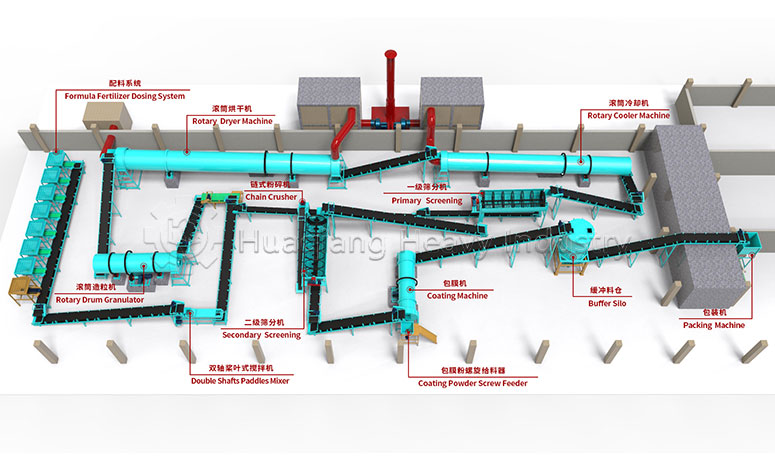

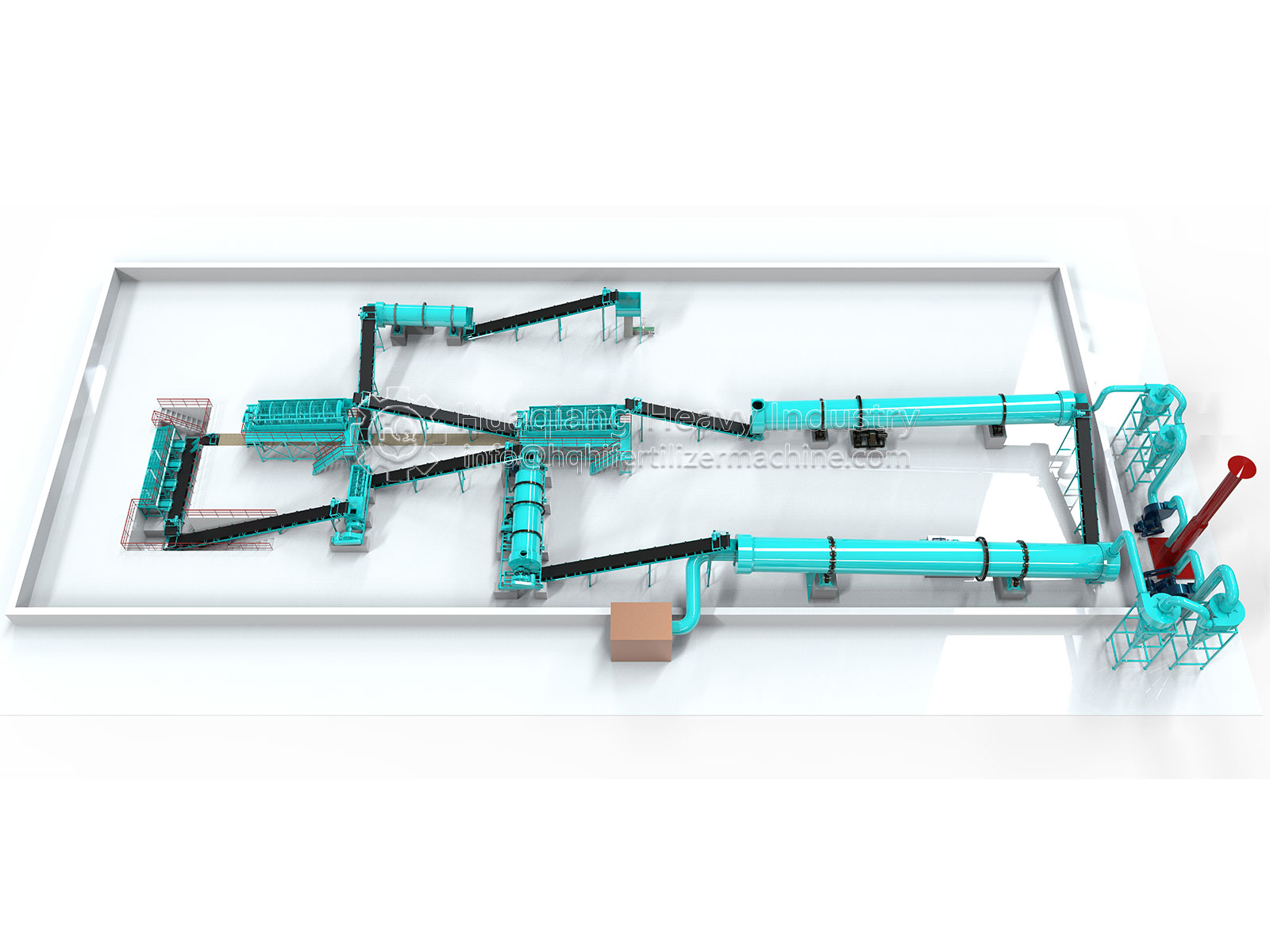

Advanced Fermentation Systems for Modern Organic Fertilizer Production

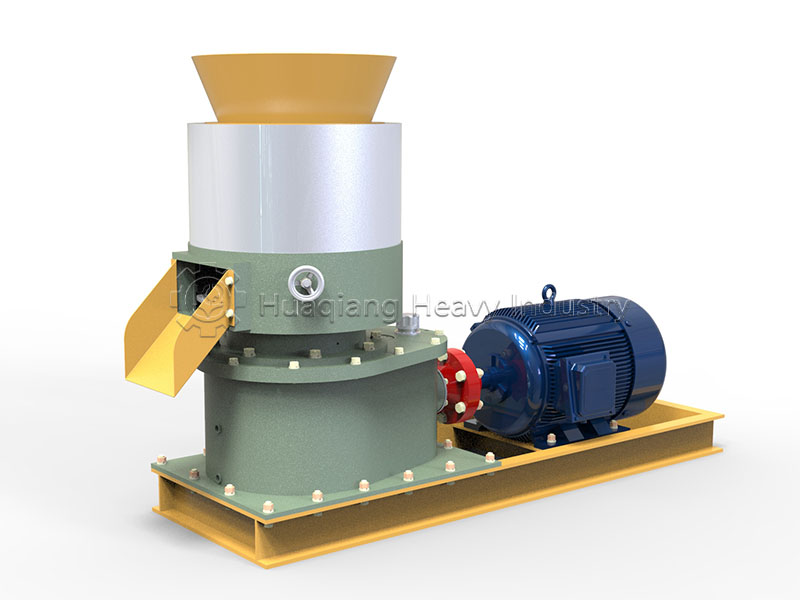

The efficiency of the organic fertilizer fermentation process is significantly enhanced by modern fermentation composting turning technology and specialized equipment. Large-scale aerobic fermentation operations utilize various turning machines, including the windrow compost turner for open-air composting, the trough-type compost turner for controlled indoor processing, and the large wheel compost turner for efficient handling of extensive windrows. For challenging materials or continuous operation requirements, the chain compost turner provides robust performance. These essential equipments required for biofertilizer production ensure optimal aeration, temperature control, and microbial activity throughout the fermentation cycle.

Following complete maturation through scientifically managed aerobic fermentation, the stabilized organic matter proceeds to a disc granulation production line for transformation into uniform, market-ready fertilizer granules. This integrated approach demonstrates how biological decomposition technologies combine with mechanical processing systems to create a complete value chain from organic waste to agricultural input. The synergy between advanced turning equipment and controlled fermentation processes not only accelerates decomposition and ensures pathogen elimination but also produces consistent, high-quality organic fertilizers that improve soil health, enhance crop productivity, and support sustainable agricultural systems worldwide. As circular economy principles gain prominence, these technologies play an increasingly vital role in transforming organic waste streams into valuable soil amendments.

.jpg)