Bio-organic fertilizer production is challenging, and these four core challenges warrant attention

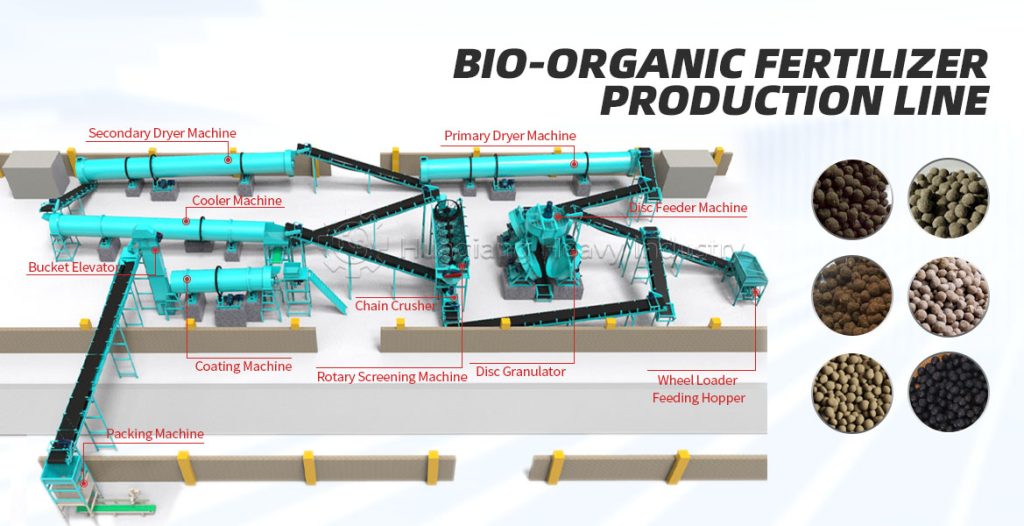

The demand for bio-fertilizers is increasing due to their green and environmentally friendly advantages and soil-improving properties. However, production faces numerous challenges due to factors such as technology, raw materials, quality control, and equipment compatibility. The compatible operation of bio-organic fertilizer production lines and rotary drum granulators also presents difficulties, hindering the industry’s large-scale, high-quality development.

Technically, controlling microbial activity is difficult, and the standardization of bio-organic fertilizer equipment and production lines is insufficient. Insufficient precision in the fermentation equipment control or incompatible parameters in the rotary drum granulator can lead to decreased microbial activity. Furthermore, the selection and acclimatization of high-quality strains is demanding and time-consuming, making it difficult to balance stability and efficiency.

Regarding raw materials, the diverse and uneven sources and quality of raw materials test equipment compatibility. Pre-treatment relies on bio-organic fertilizer equipment; insufficient compatibility makes impurity removal difficult. Rotary drum granulators are prone to problems such as loose granules and low forming rates due to uneven raw material distribution. Incomplete raw material decomposition and unstable supply also affect production.

At the quality control level, industry standards are inconsistent and testing is cumbersome. Most bio-organic fertilizer production lines lack precise quality control equipment, making it difficult to monitor the finished product from the rotary drum granulator and materials at each stage throughout the process. This easily leads to problems such as substandard microbial content and unbalanced nutrients.

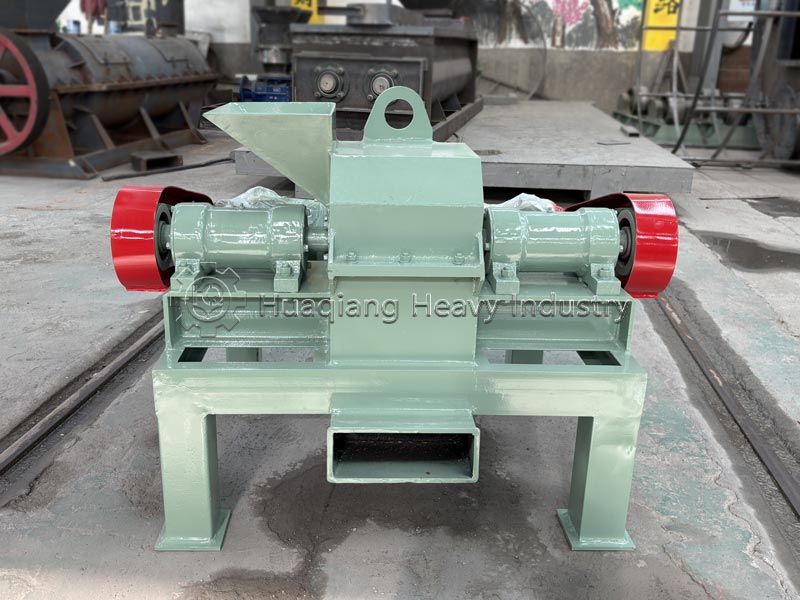

At the market level, misconceptions and homogeneous competition are prominent. Some producers use rudimentary bio-organic fertilizer equipment without standardized production lines and rotary drum granulators, simplifying processes to reduce costs, further exacerbating market chaos.